This is a useful information site that provides technical explanations and case studies related to Dyden products.

All Articles

-

2023.3.1

- Electrical Wires and Cables

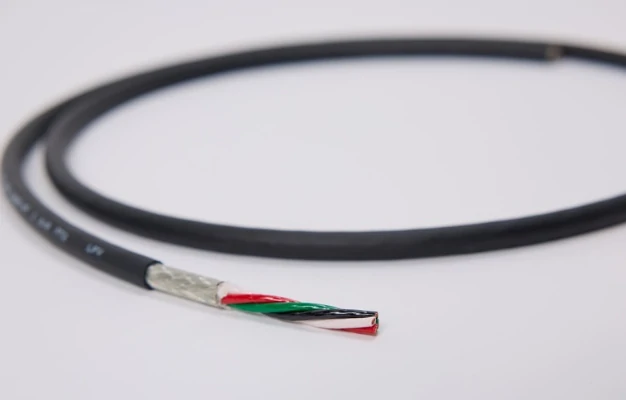

What are robot cables?

We will explain aspects of robot cables in an easy-to-understand manner, from an overview of those cables to the features of Dyden’s cables and selection of robot cables.

-

2023.3.1

- Electrical Wires and Cables

Proposal of special conductor, special shield, and special jacket

We suggest optimum robot cables with special conductors, special shields, and special jackets for our customers’ various operating environments.

-

2023.3.1

- Electrical Wires and Cables

Request for durability testing and calculation of flexural life

We will explain the durability testing of robot cables that we conduct according to customer requests.

We will also introduce cable life simulation software. -

2023.3.1

- Electrical Wires and Cables

The recommended bend radius for robot cables

We describe the materials for and composition of conductors and insulators used in our robot cables.

-

2023.3.1

- Electrical Wires and Cables

Reasons for material selection and composition of conductors and insulators

We will explain aspects of robot cables in an easy-to-understand manner, from an overview of those cables to the features of Dyden’s cables and selection of robot cables.